Looking to buy a steel building and came across the term “prefabricated steel buildings”? And now you’re doing some research on what that actually means? Don’t worry, you’re in the right place. In this blog, we will walk you through exactly what that term means and why it matters for your project.

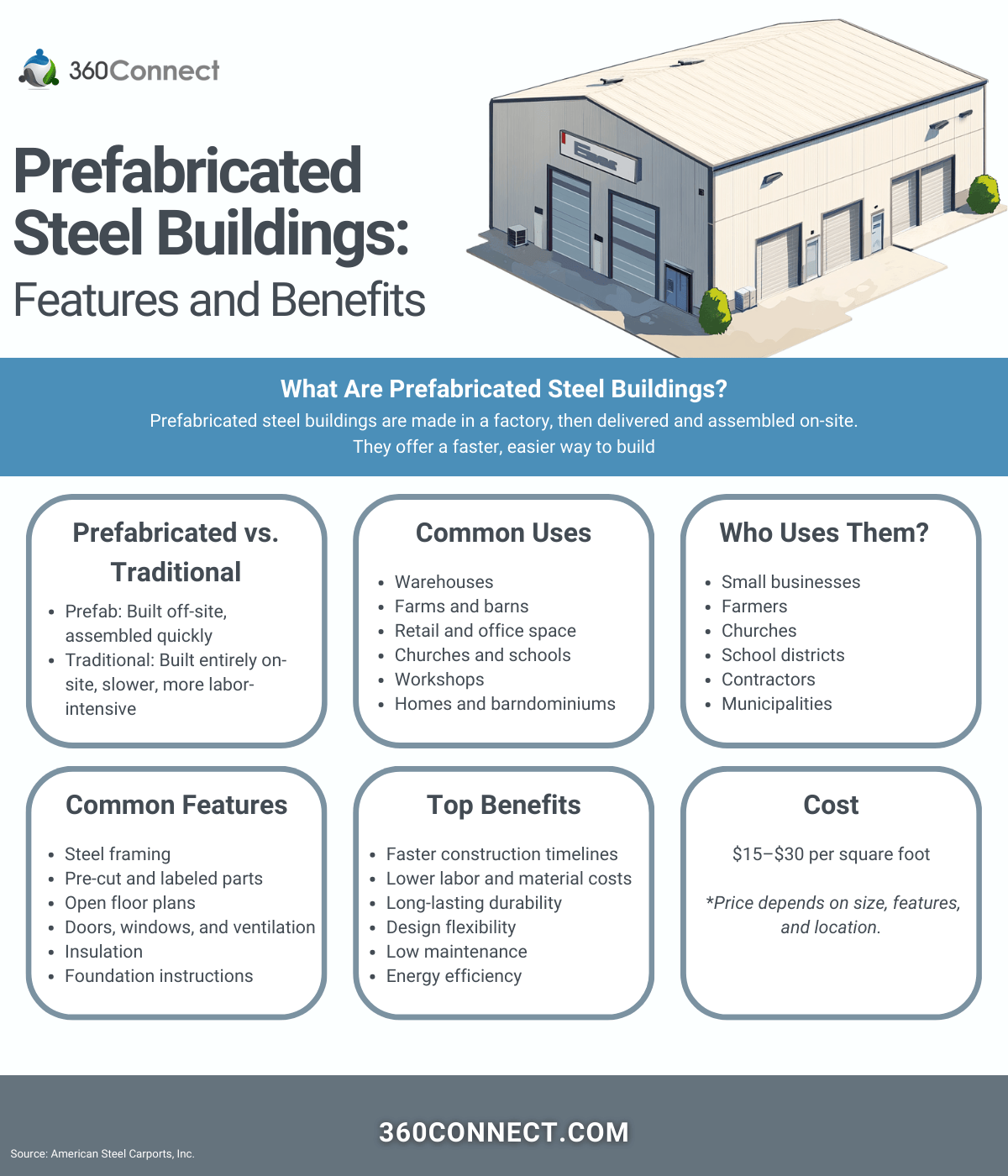

At first glance, it might sound a bit technical, but it’s actually a simple concept. Prefabricated steel buildings are built in a factory, and then delivered and assembled at your location. It’s a faster and more efficient way to build, and it’s becoming more popular every year. In fact, the global prefabricated building market is projected to reach $202.7 billion by 2030.

In the sections below, we’ll explain what prefabricated steel buildings are, how they compare to traditional construction, what they’re used for, who typically uses them, what features you can expect, and how much they cost. Let’s break it down.

What Are Prefabricated Steel Buildings?

Manufacturers create prefabricated steel buildings in a factory, and then crews assemble them on-site. The key components, such as the frame, wall panels, and roof systems, are pre-cut, pre-welded, and pre-drilled to fit together quickly and accurately. This process reduces the amount of time and labor needed for construction.

Once the supplier delivers the building, crews assemble it like a kit. Manufacturers label, organize, and engineer each part to fit together seamlessly. Engineers design these buildings to meet local codes, and you can customize the size, shape, and layout to fit your project. Builders choose prefabricated steel buildings because they’re durable, low-maintenance, and quick to install.

Prefabricated vs Traditional Construction

So, what is the difference between prefabricated and traditional construction?

Traditional construction builds the structure entirely on-site. That means every wall, beam, and support is measured, cut, and assembled at the location. This process often takes longer and can be more expensive due to weather delays, labor shortages, and material waste.

Prefabricated construction, on the other hand, shifts most of the work to a controlled factory environment. The components are manufactured with precision and shipped ready to assemble. This allows for better quality control, faster timelines, and reduced costs.

If you are looking for a streamlined, efficient building process, prefabrication is a smart alternative.

What Are Prefabricated Steel Buildings Used For?

Prefabricated steel buildings are used in a wide variety of industries and applications. Their strength, adaptability, and cost-effectiveness make them a go-to solution for many types of projects. Some of the most common uses include:

- Warehouses and storage facilities

- Agricultural buildings like barns and equipment shelters

- Office spaces and retail storefronts

- Churches and community centers

- School gymnasiums and classrooms

- Manufacturing plants and workshops

- Aviation hangars

Whether you need an open floor plan, a multipurpose space, or specialized features, prefabricated steel buildings can be tailored to fit.

Who Uses Prefabricated Steel Buildings?

These buildings are used by a wide range of people and organizations. Indeed, they are not limited to one industry or business size. Some common users include:

- Small business owners who need affordable commercial space

- Farmers who require reliable and weather-resistant storage

- School districts expanding their facilities quickly

- Churches building sanctuaries or fellowship halls

- Contractors who need portable offices on job sites

- Municipalities looking for cost-efficient public works buildings

Businesses and organizations choose prefabricated steel buildings because they’re accessible and flexible, making them a fit for many different scenarios.

What Are the Common Features of Prefabricated Steel Buildings?

Even though you can customize each building, most prefabricated steel buildings come standard with features that keep the process simple and efficient:

- Steel framing that provides strength and stability

- Pre-drilled holes and clearly labeled parts for faster assembly

- Clear-span designs with no interior support columns

- Custom options for windows, doors, skylights, and ventilation

- Foundation anchor plans and detailed installation instructions

Depending on your needs, you can also include features like insulation, interior walls, and more.

Benefits of Prefabricated Steel Buildings

There are many reasons why people choose prefabricated steel buildings over other types of construction. Here are some of the most important benefits:

Faster Construction

Since the components arrive ready to assemble, builders can complete many projects in weeks instead of months. This helps you move into your space faster and start using it sooner.

Lower Cost

Labor costs are lower since less work is needed on-site. There is also less material waste and fewer delays, which saves money overall. Long-term maintenance costs are lower too, thanks to steel’s durability.

Strength and Longevity

Builders design steel buildings to last. They resist pests, rot, mold, fire, and harsh weather. They hold up for decades with minimal upkeep, making them a smart long-term investment.

Design Flexibility

You can customize the layout, size, color, and interior features. Whether you need a simple warehouse or a fully finished office, there is a prefab solution that fits.

Environmental Efficiency

Prefabrication reduces construction waste. Many steel materials are recycled or recyclable, and energy-efficient options like insulated panels are widely available.

How Much Do Prefabricated Steel Buildings Cost?

The cost of prefabricated steel buildings can vary based on several factors. On average, you can expect to pay between 15 and 30 dollars per square foot for the building itself. Here is what influences the total price:

- Building size and shape

- Custom design features

- Location and shipping costs

- Type of foundation required

- On-site labor and installation

Keep in mind that interior remodeling, insulation, and finishing work are usually separate from the initial building cost.

Final Thoughts

If you are looking for a practical, cost-effective way to build, prefabricated steel buildings are well worth considering. They combine strength, speed, and flexibility into one package and can serve almost any purpose. Additionally, you do not need to be a construction expert to take the first step. With a little research and the right supplier, you can bring your vision to life quickly and confidently.

Get Steel Building Quotes Today

Interested in learning more? We can help you compare quotes from top steel building suppliers, so you can find the right option for your needs and budget. It is fast, free, and designed to connect you with professionals who understand your goals.